Polski

Manufacturer and supplier - Air filters for recuperators, heat pumps and mechanical ventilation systems.

We offer a wide selection of air filters for HVACR ventilation systems. We specialize in manufacturing customized filters to meet individual customer needs. We make each filter based on current air filtration standards with high-quality materials, ensuring maximum filtration efficiency and long life. With our filters you will take care of clean and healthy air in your home, office or industrial plant. Check our offer and order the perfectly matched filter for your device!

Not sure what filter to choose? Leave your phone number, we'll call you back and help you choose.

We manufacture filters for the following brands of equipment

We manufacture high-quality replacement and equivalent filters for equipment from respected brands.

Our filters guarantee a perfect fit for a variety of ventilation systems, and we also offer a range of replacement products with increased filtration efficiency for even better air protection. Thanks to precision manufacturing and the use of modern materials, our products are distinguished by long life and high filtration efficiency. Choose a matched filter according to your needs for your device and enjoy cleaner air!

Rated at

Air filters

How to choose the right filter for your device?

Use our breakdown and simple guide to quickly find the perfect filter for your device. If necessary, we’ll help you with your selection step by step!

Recuperator breakdown

Check out the breakdown of filters by model and brand of HVACR equipment to easily find the product that fits your ventilation, heating or air conditioning system.Air filters

Choose the right air filter that will provide effective filtration and fit your device. Check out our offer!Filter foams

We offer filter foams of various densities, ideal for filtration of air, liquids, water and gases. Used as a filter in compressors, separators, purifiers and other equipment.Non-woven filter fabrics

Non-woven filter fabrics perfect for various ventilation systems. Choose the right density and filtration efficiency for your unit!Help from our specialist

Still not sure which filter to choose? Contact our specialist, who will help match the perfect solution for your device!

Murano Phoenix - Experts in manufacturing customized air filters

Murano Feniks to firma z wieloletnim doświadczeniem w produkcji wysokiej jakości filtrów powietrza, które spełniają najwyższe standardy filtracji. Specjalizujemy się w produkcji filtrów na wymiar, dzięki czemu nasze produkty są idealnie dopasowane do różnych urządzeń i systemów wentylacyjnych, takich jak rekuperatory czy pompy ciepła oraz systemy antysmogowe.

Szybka realizacja zamówień, 7 – 10 dni w przypadku produktu na zamówienie. Nasza wiedza i zaangażowanie pozwalają nam oferować rozwiązania skrojone pod konkretne potrzeby klientów. Zaufaj ekspertom od czystego powietrza – wybierz Murano Feniks!

Murano Phoenix is a company with many years of experience in manufacturing high-quality air filters that meet the highest standards of filtration. We specialize in the production of customized filters, making our products perfectly suited to various devices and ventilation systems, such as recuperators or heat pumps and anti-smog systems.

Fast order processing, 7 – 10 days for customized product. Our expertise and dedication allow us to offer solutions tailored to your specific needs. Trust the experts in clean air – choose Murano Phoenix!

Production of customized filters

If you do not find a filter matching your needs among the offer of our store, we will make it for you on an individual order - according to your requirements and specifications. All you need to do is provide us with its dimensions and you can also provide us with a photo of the filter you are currently using in order to facilitate the selection of the type of manufacture of the appropriate product.

Write to our specialistWhen do you need a custom filter?

Our company offers customized solutions when standard filters do not meet your requirements, or you have to wait a very long time for filters for your device, or they are no longer available or cannot be found. The process begins by contacting our sales department and R&D team, who carefully analyze your needs. This allows us to create a filter that is perfectly matched to the technical requirements, specific dimensions and operating conditions in which it will be used.

What do you gain by producing a filter in our company?

When you choose to manufacture your filter at Murano Phoenix, you get high quality at an attractive price. We offer fast turnaround times to minimize or eliminate downtime in your operation. Our experience and commitment guarantee that you will receive a perfectly tailored product that meets all technical and environmental requirements.

What does this process look like?

After gathering all the necessary information, we proceed. In a short period of time, we develop the appropriate technological solutions to start producing filters tailored to individual requirements. The entire process proceeds in the same way as in the production of our standard filters – with the utmost precision and attention to quality.

What is the waiting time for production?

We assume a lead time of 7-10 business days for custom products, and 1 business day for in-stock products.

What customers say about our air filters

Kamil Banasik

Client

Super modern company with unique solutions for its customers. Professional and understanding service. What more to want, I will recommend to any owner of ventilation systems

Konrada Skibińska

Customer

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet.

Jarosław Sierociński

Client

Very reliable company, customer service at the highest level. Everything was handled efficiently and very friendly service. I have no reservations at all. Quick to respond to needs, quality of products at a very high level.

Norbert Kamiński

Client

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet.

Miroslaw Maniecki

Client

The order I placed for filters at Murano Phoenix was completed quickly and perfectly without any problems. I recommend 100%

Marek Jabłoński

Client

Efficient processing of the order, filters fit my device perfectly. I recommend 100%.

Murano filters - check what filters we produce

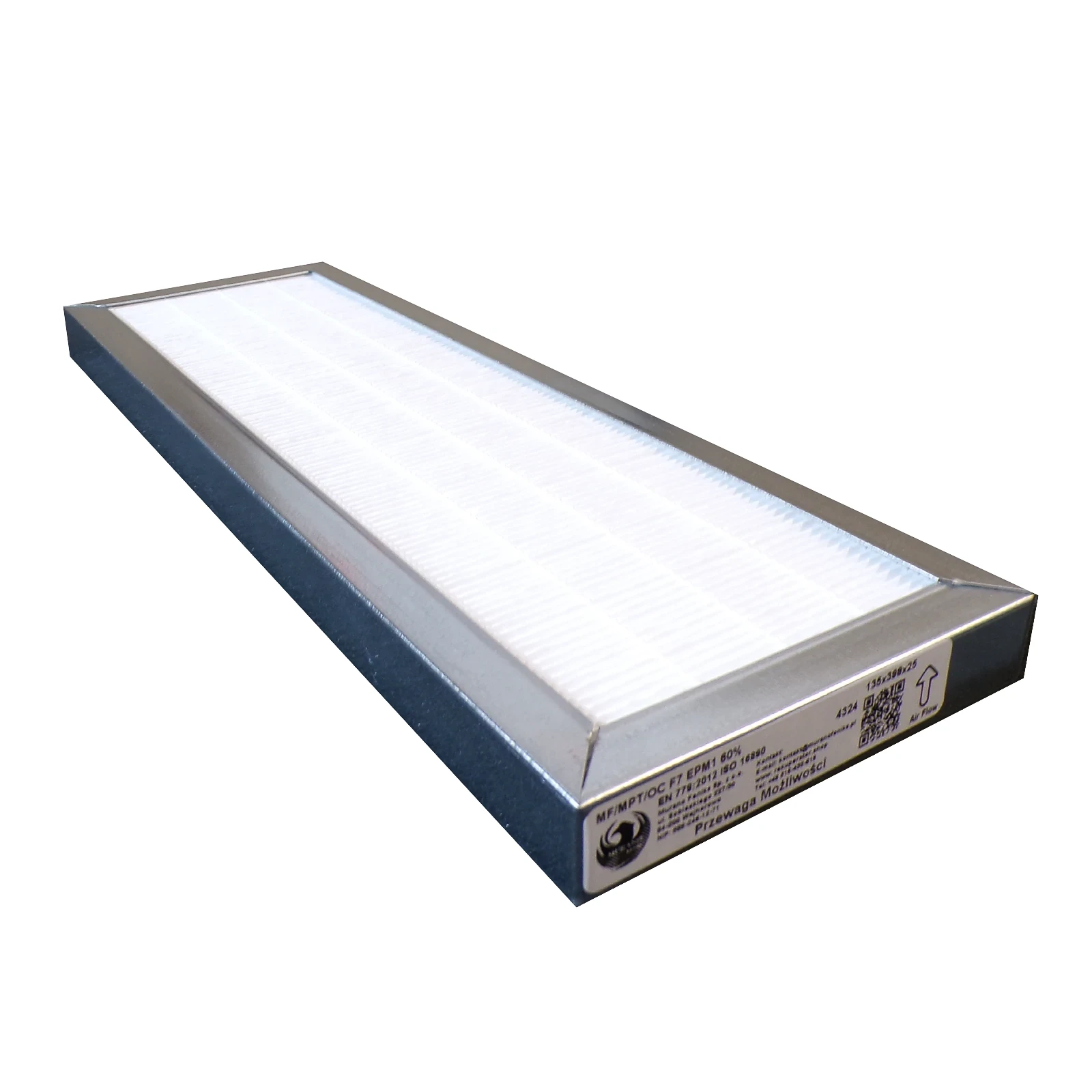

Flat Filters

Flat filters are essential components of ventilation systems, effectively stopping larger contaminants, such as dust, pollen or pollen. Made of high-quality materials synthetic materials, embedded in a frame, ensure high efficiency and low resistance to air flow. Their compact design makes them, that they are easy to install and replace. Used mainly as filters pre-filters, they effectively protect subsequent system components from excessive contamination contamination. We manufacture flat filters in any size, offering classes of G3, G4 and M5 filtration classes. The structure can be based on a frame or frames made of metal, cardboard or plastic of 20 mm and 25 mm thick.

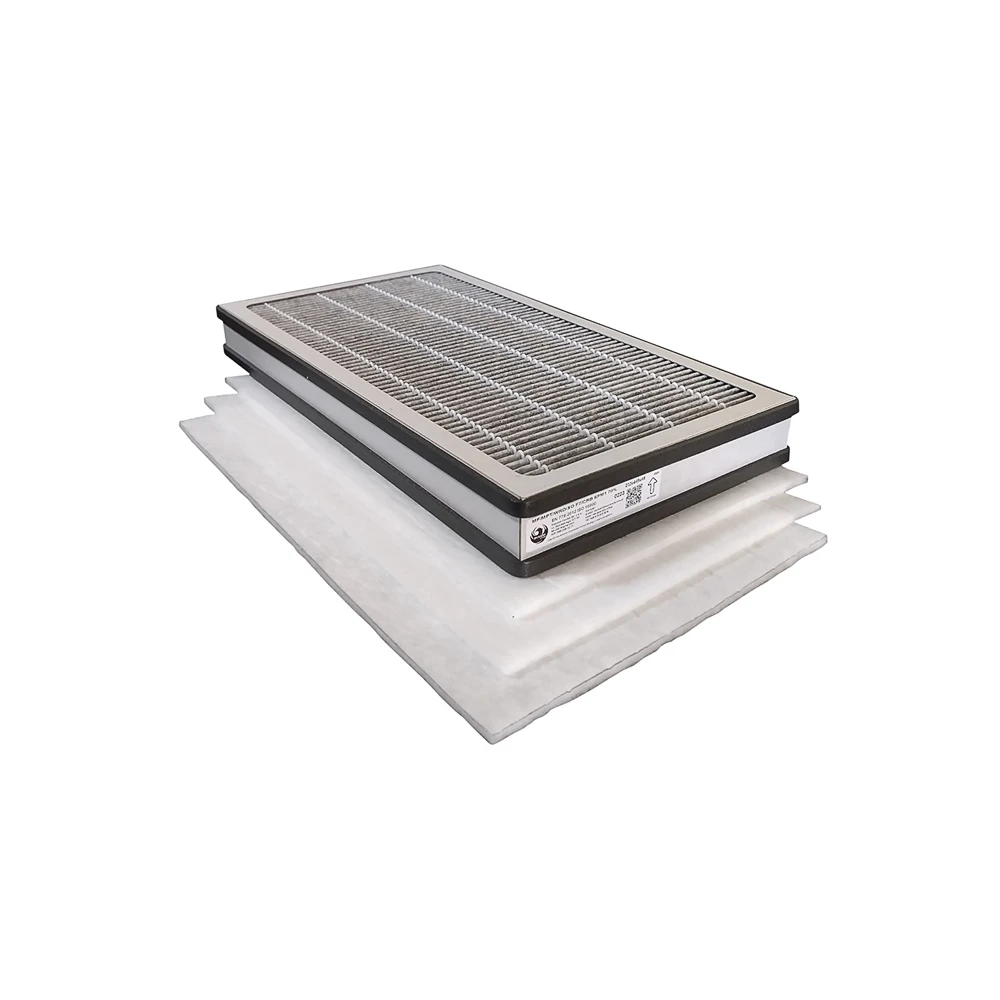

Cartridge Filters

Cartridge filters are distinguished by their rigid construction, in which the filter medium filter medium in the form of an accordion is embedded in a sturdy frame made of metal, cardboard or plastic. Thanks to their enlarged filter area, they provide high efficiency and extended service life. They are ideally suited as preliminary and fine filters in ventilation and air conditioning systems. We manufacture cartridge filters in any size in filtration classes G3, G4, M5, M6, F7, F8 and F9. Versions with plastic frames are available in thicknesses of 20 mm, 25 mm, 48 mm, 96 mm and 130 mm.

Pocket Filters

Pocket filters are an efficient solution for HVAC systems, consisting of several chambers (pockets) made of high-quality polyester, synthetic or glass non-woven fabric. Embedded in a galvanized steel or plastic frame, they provide an optimal filtration surface and excellent efficiency in retention of fine dirt particles. We manufacture pocket filters in any size, offering classes of G3, G4, M5, M6, F7, F8 and F9 filtration. The plastic frames are available in thicknesses of 20 mm and 25 mm.

Grease Filters

Grease filters effectively trap grease and oil particles floating in the air, providing essential protection for ventilation systems in industrial kitchens, restaurants and manufacturing plants. Made of properly woven knitted fabric of galvanized steel , they can be repeatedly cleaned and reused reused. Their use reduces the risk of fire and keeps ventilation installations clean. We make grease filters in any size, adapting them to the specific needs of our customers.

Carbon Filters

Carbon filters are irreplaceable in the elimination of unpleasant odors and volatile organic compounds (VOCs) from the air. Thanks to application of activated carbon they effectively neutralize pollutants gaseous pollutants, which makes them applicable in kitchens, laboratories and industrial facilities. Our offer includes carbon filters in the form of cartridge filters with material enriched with activated carbon (filtration classes G4 or F7) and batch filters, in which the cassette is filled with granular activated carbon. All models are available in any size.

Conical Filters

Cone filters are solutions with specialized applications, used mainly in industry and ventilation systems requiring low airflow resistance and optimal filtration performance. Their cone-shaped design allows for efficient use of space. These filters can be made of a variety of filter materials, tailored to the specific application.

Filters Absolute

Absolute filters (HEPA - High Efficiency Particulate Air) are the highest filtration standard, trapping even the finest particles, including bacteria, viruses and allergens. Made of ultrafine fibers glass fibers, they provide the highest level of air purity. They are used in laboratories, hospitals and clean rooms, where air quality is crucial. We make HEPA filters to individual order, in any size, tailored to your specific needs.

Filter Foams

PPI filter foams, made of flexible polyurethane with an open cell structure, are versatile filter materials. They are used in ventilation, automotive, industrial and liquid purification applications. Thanks to their different densities, they can act as air filters, acoustic silencers and mechanical separators.

Filtration Nonwovens

Nonwoven filter fabrics are a key component in many types of filters. Made of synthetic and polyester fibers, often reinforced with a mesh, they provide high efficiency in retaining contaminants. They are used in flat, cartridge and pocket filters, where their parameters are individually selected to meet the requirements of the requirements of the system.

Customized air filters - Polish production, highest quality, clean air

Frequently asked questions about air filters

They are no different from the original ones when they are made in accordance with current standards. Just like the original filters, they must meet the filter performance requirements set by a number of different standards. Filters may differ in workmanship by design, but the filtration parameters for the level of filtration may even be higher when using a filter made in a higher class. In addition, many manufacturers of air handling units order their filters from filter manufacturers. Thus, many times it can happen that the replacement filter differs only in the label.

The dimensions of sealed filters are given separately for the frame and gasket. Namely, the dimension of the frame plus the thickness of the gasket with a pitch of 1-2 [mm].

Check the nameplate for the make and model of your appliance, or measure the filters in your appliance and compare with the dimensions shown in the product description. Determine what filtration class of filters you need for yourself and your family. The letter denotes the filter group and the number refers to the efficiency thus the G4 filter retains much less pollution than the F7 filter. It is worth noting at this point that fine filters of group F retain particles harmful to Our health. Therefore, we also recommend using them on the supply and on the exhaust we suggest using the medium class M or coarse class G . Regarding the filter area, the larger the filter, the longer the filter operation and less frequent the replacement. Filter area is the amount of material placed in the filter frame. Surfaces of different types of filters, assuming the same dimension, from the smallest to the largest: flat, pleated, plot, minipleat.

Filters need to be replaced when they are fully soiled or once every 6 months. Dirty filters are dark you can see insects and dust and other impurities on them. Commission Regulation (EU) No. 1253/2014 requires manufacturers to install devices in air handling units that indicate when the filter needs to be changed. Indicators include a timer and a pressure device:

The timer is usually set for a specific period of time, such as 90 days. You can check if the filter is dirty and then set the timer according to your actual needs.

Pressure indicators measure the pressure drop on the filter. Therefore, it is necessary to change the filter when the dirt indicator turns on.

Note that failure to replace filters on time may lead to the voiding of the air handling unit manufacturer’s warranty. In addition, dirty filters result in higher energy bills.

No, air filters have an arrow on the rating label indicating the direction of air flow through the filter. Thus, the filter should be installed according to its indication or description on the label. Reverse installation results in increased air resistance and faster filter wear.

When creating your own set of filters for your recuperator, it is worth considering their purpose. Are they only to protect the ventilation system, or also to take care of air quality and our health?

If we care only about protecting the system, G4 or M5 filters on the intake/supply and exhaust/exhaust are sufficient. On the other hand, if the priority is cleaner air free of fine pollutants, it is worth using more precise F7, F9 or F7 filters with activated carbon on the intake / supply. On the exhaust/exhaust remain G4 or M5, because the air here is removed from the building and does not require advanced filtration.

Note that fine filters have higher air resistance and wear out faster, so their use is recommended on the intake / supply.

Grease filters and polyurethane mats can be safely cleaned with water and detergent. Their design allows washing, and regular cleaning is even recommended. After washing, the filter should be rinsed thoroughly and allowed to dry completely before reuse.

In the case of coarse and fine filters, such as G4, M5, F7 or F9, any attempt at cleaning – vacuuming, blowing or washing – leads to damage to the structure of the filter material. These filters act like a sieve, thickening toward the outlet side, which means that they retain finer and finer contaminants deep into their structure. Mechanical cleaning can result:

- Blowouts, or localized damage to the strands, through which air will pass without filtration.

- Tearing of the fibers, which reduces the efficiency of particle capture and shortens the life of the filter.

- Clumping of the filter material, especially after washing, which leads to reduced airflow and can promote microbial growth.

Consequently, a damaged coarse filter can generate more air resistance, and a fine filter will lose its cleaning ability, letting contaminated air through. Therefore, instead of trying to regenerate, it is recommended to regularly replace the filters with new ones.

The choice of filter frame for a recuperator depends on the operating conditions. Cardboard frames are lightweight and environmentally friendly and work well in home systems, but are sensitive to high humidity. Metal ones, made of steel or aluminum, are durable and resistant to harsh conditions, so they are often used in industry. Plastic ones, most often made of ABS or PP, are lightweight, resistant to moisture and work well where there is increased humidity. For the home, a cardboard one will usually suffice, while in more demanding conditions it is better to choose a metal or plastic one.

Place an order and receive another identical one for FREE!

Competition with phoenix murano

Place an order for filters from the store or custom filters. The contest is held every month for people who have shopped with us in the last 5 months. 3 people win.

Murano Feniks Ltd.

227/30 Sobieskiego St., 84-200 WejherowoBank Account

Bank name: Santander Bank Polska S.A.

Account no: EN 16 1090 1102 0000 0001 4691 5627

SWIFT: WBKPPLPPCheck our account on the white list: https://www.podatki.gov.pl/wykaz-podatnikow-vat-wyszukiwarka

Payer details

NIP: 588-246-12-71

NIP EU: PL588-246-12-71

REGON: 386967800Entry in the National Court Register (KRS) under the number 0000858484 in the District Court in Gdańsk VIII Gosp. Wydział KRS. Share capital 5.000,00 PLN

- +48 516 433 819

Phone number

We are available at this phone number

- kontakt@muranofeniks.pl

E-mail

We are available at the following email address

Address

ul. Sobieskiego 227/30, 84-200 Wejherowo

Write to us

Contact form

Do you have questions or need help selecting a filter? Use our contact form - we will respond as soon as possible!